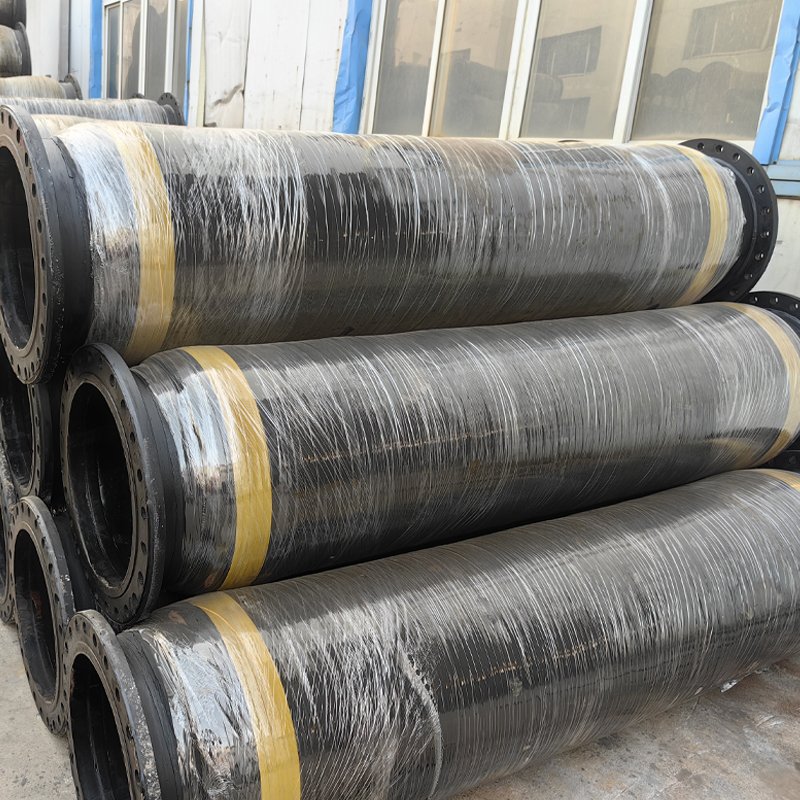

Dredging Rubber Hose

As technology continues to advance, rubber dredging hose are taking on an increasingly important role in dredging pipelines. Unlike traditional dredging pipelines, rubber drainage pipes leverage their unique flexibility and adaptability to compensate for the shortcomings of steel pipes and HDPE drainage pipes, providing the optimal solution for dredging projects in harsh environments.

Structure: Inner lining wear-resistant layer: directly in contact with the conveying medium to provide wear-resistant protection. Reinforcement layer: made of high strength fiber or steel wire weaving, which gives the pipe the ability to withstand pressure. Outer rubber layer: protective and reinforcing layer, with anti-aging, corrosion resistance and UV resistance.

Characteristic: Excellent flexibility: The rubber hose is extremely flexible and can adapt to complex terrain and harsh Marine environment, which can easily bypass obstacles, reduce connection points and reduce leakage risk. Excellent wear resistance: the lining of the pipe is wear-resistant rubber, which can effectively resist the wear of mud and sand, and significantly extend the service life.Good corrosion resistance: rubber has good acid and alkali resistance,can resist sea water corrosion.Light weight and easy installation: compared with steel pipe, rubber hose is lighter in weight, which is convenient for transportation and installation, greatly improving the construction efficiency.Reduce noise: rubber material can absorb noise, reduce the noise pollution to the surrounding environment.

Application: suitable for river bends, sea, narrow water areas, regions with large temperature differences between day and night, and areas with dense submarine pipelines, etc., which can flexibly respond to terrain changes. Short distance transportation: such as dredging and land reclamation operations, can achieve rapid deployment and disassembly.Wear-resistant requirements: when conveying a large amount of materials such as gravel, pebbles, shells and coral reefs containing gravel, it can effectively resist wear. Areas with high environmental protection requirements: such as close to residential areas, ecological environment protection areas, etc., can effectively reduce noise and vibration.

Selection factors : Conveying medium: the characteristics such as grain size, concentration and density of silt should be considered.Work pressure: determine the appropriate pressure according to the conveying distance, discharge height, etc.Working environment: including water depth, flow rate, temperature and other factors.Engineering requirements: including transportation capacity, engineering cycle and so on.

Attention: Avoid excessive bending: prevent damage to the internal structure of the pipe.Control working pressure: shall not exceed the rated working pressure.Regular inspection and maintenance: timely detection and repair of damaged parts.