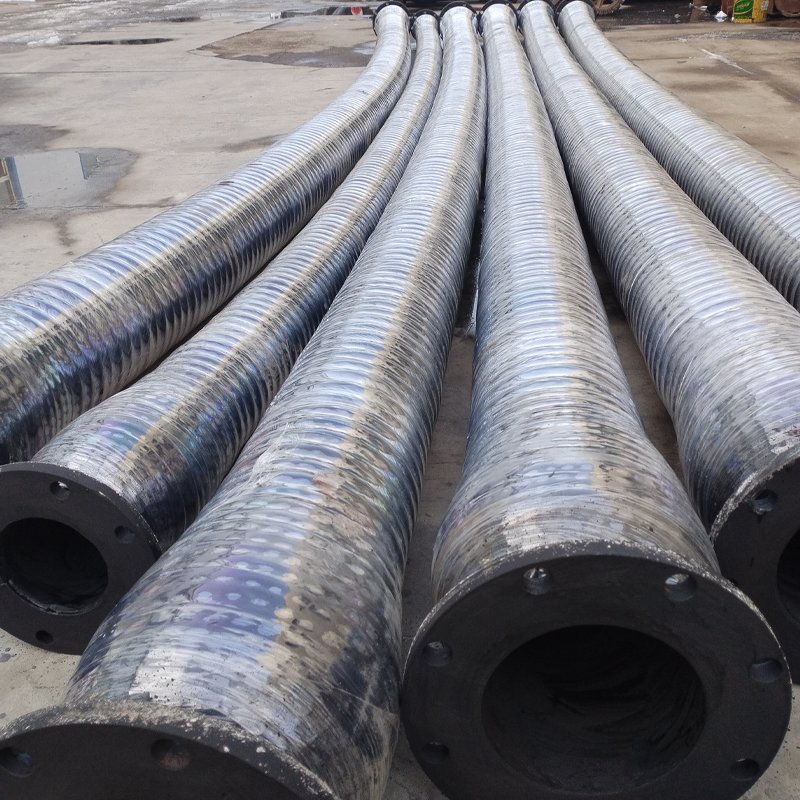

Armored Dredging Submerged Hose

Underwater dredging armored rubber pipe is a heavy-duty hose specifically engineered for underwater dredging operations. It ingeniously integrates the flexibility of rubber with the compressive and tensile properties of the armored structure, making it highly suitable for various demanding scenarios. This type of pipe is widely applied in river dredging, port construction, submarine mining, and other fields. The following is a detailed elaboration on its key features and applications:

Core structure and materials:Inner glue layer:The inner glue layer is crafted from wear-resistant rubber materials, such as natural rubber, styrene butadiene rubber, or polyurethane. These materials endow the pipe with excellent resistance against the erosion and abrasion caused by silt and gravel.In certain designs, corrosion-resistant coatings are added to effectively withstand the corrosive effects of seawater or chemicals, ensuring the pipe’s durability in harsh environments.Reinforcement layer:Multi-layer fiber braid/winding layer: Composed of polyester or nylon, this layer provides the pipe with robust compressive and tear resistance, enhancing its structural integrity.Wire Armor: High-carbon steel wire or stainless steel wire is spirally wound to form the wire armor. This significantly improves the pipe’s tensile resistance, effectively preventing deformation due to suction forces or external impacts during underwater operations.Outer layer:The outer glue layer is made of weather-resistant rubber, such as neoprene. This material offers excellent protection against UV radiation, seawater erosion, and biological adhesion, including barnacles, thereby extending the service life of the pipe.Accessories and Connections:The pipe is equipped with flange, quick connector, or clamp designs. These components ensure a secure and tight connection with dredging pumps and ship piping systems, effectively preventing leakage and guaranteeing smooth operation.

Key Performance Advantages:High wear resistance: The pipe is designed to endure long-term transportation of solid particles. Its wear rate is less than 0.1cm³/1.61km, ensuring reliable performance even in abrasive environments.

Negative pressure resistance: Thanks to the armored structure, the pipe body can resist collapse during the suction process. It can withstand a working negative pressure of up to -0.09MPa, making it suitable for various suction-based dredging operations.Dynamic adaptability: With a flexible design, the pipe allows a bending radius of at least 5 times its diameter. This feature enables it to adapt to the movement of ships and underwater equipment, providing great convenience during installation and operation.Float control: The pipe can be paired with floats or heavy chains, allowing for precise control over its underwater posture. This ensures stable operation and efficient material transportation.

Applications:Sailing Dredging:In sailing dredging projects, such as the deep-water channel projects in the Yangtze River Estuary, this pipe is used to clean up silt, sand, and gravel, effectively maintaining the navigation depth and ensuring the safe passage of ships.Sea Mining:For sea mining operations, the pipe is employed to convey manganese nodules and rare earth slurry. The armored layer can withstand the high pressure of the deep sea, enabling it to operate at a working depth of up to 200 meters.Environmental dredging:In environmental dredging tasks, the pipe is used to clean up polluted bottom sludge. The rubber material of the pipe helps avoid secondary pollution, contributing to environmental protection.Emergency rescue:During emergency situations, such as after flooding, the pipe can be used for silt cleaning or rapid pipeline deployment, playing a crucial role in rescue and recovery efforts.

selection and maintenance:Selection parameters:Pipe diameter: Common pipe diameters range from 150mm to 600mm. The appropriate diameter should be selected based on specific project requirements.Working pressure: The pipe can operate under a working pressure ranging from 0.6MPa to 2.5MPa. It is essential to choose a pipe with a suitable pressure rating according to the operational conditions.Media particle size: The particle size of the conveyed media needs to be matched with the hardness of the internal glue layer to ensure optimal performance and prevent premature wear.Armor type: For shallow water applications, a lightweight armor type, which combines fiber and wire, is recommended. In deep water or rocky environments, a heavy-duty full wire armor type is more suitable to withstand the harsher conditions.Maintenance suggestions:Regularly inspect the outer glue layer for cracks and the armor for rust, especially in seawater environments. Promptly address any detected issues to prevent further damage.When storing the pipe, avoid folding it to prevent plastic deformation of the steel wire layer, which could affect its performance and lifespan.